Flare System Design Basis

Flare system design basis. Revision issue date by iocl_flare_design_basis_rev1doc 12605 1 march 2 2005 aarpt table of contents 1. For more visit here. The process design project included completion of the following tasks.

Signature Date Name Project Management Services for Rabigh Phase II Petrochemical Project DESIGN BASIS FOR FLARE SYSTEM JGC Job Code. This includes a refinery capacity evaluation etc. Download Flaretot Pro v139 flare system design.

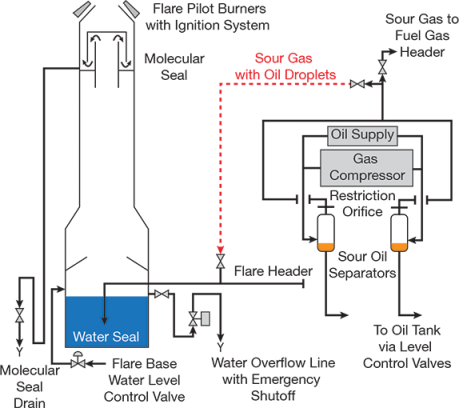

The burner often includes one or more pilots pilot igniters and pilot flame detectors. We process engineering supports to simulate the flare system design projects. If you are author or own the copyright of this book please.

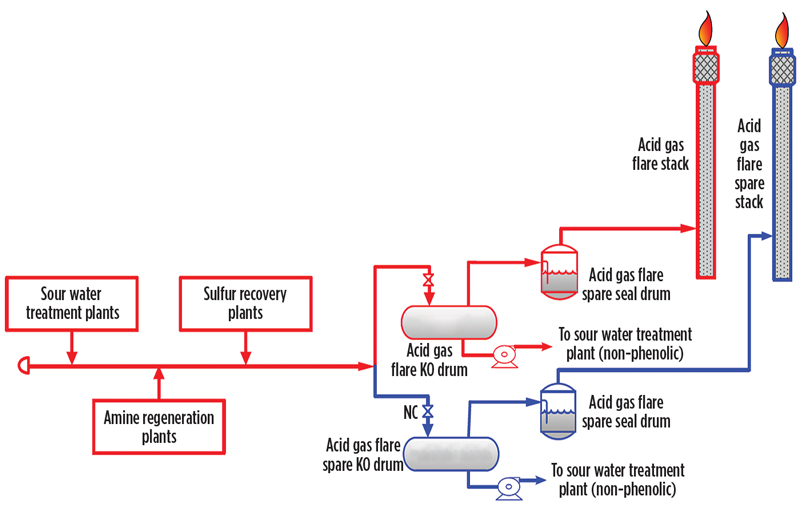

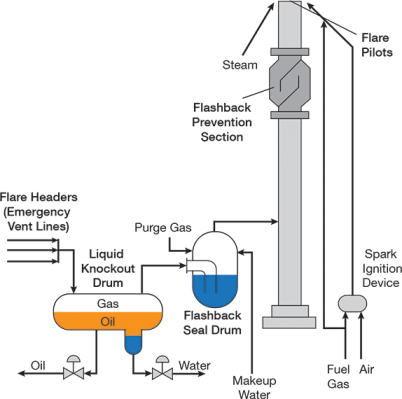

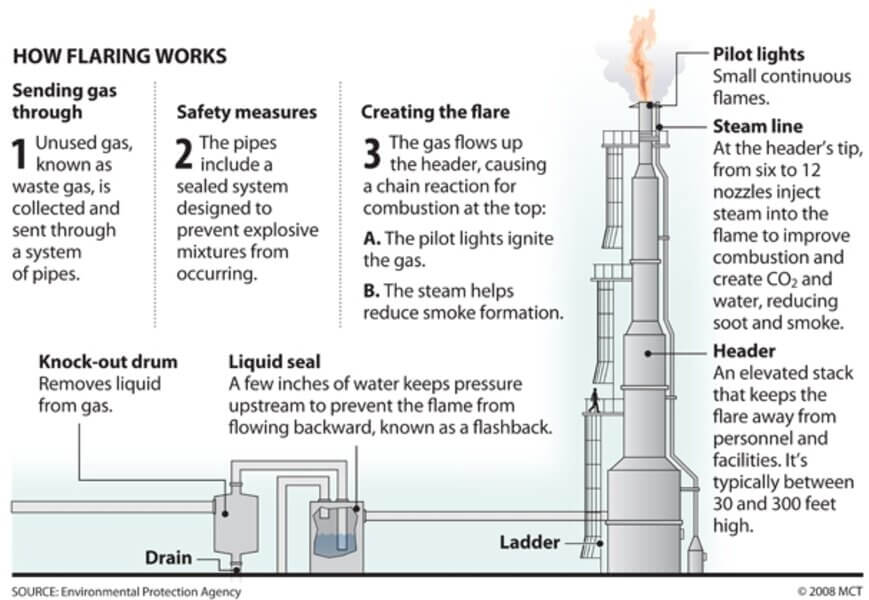

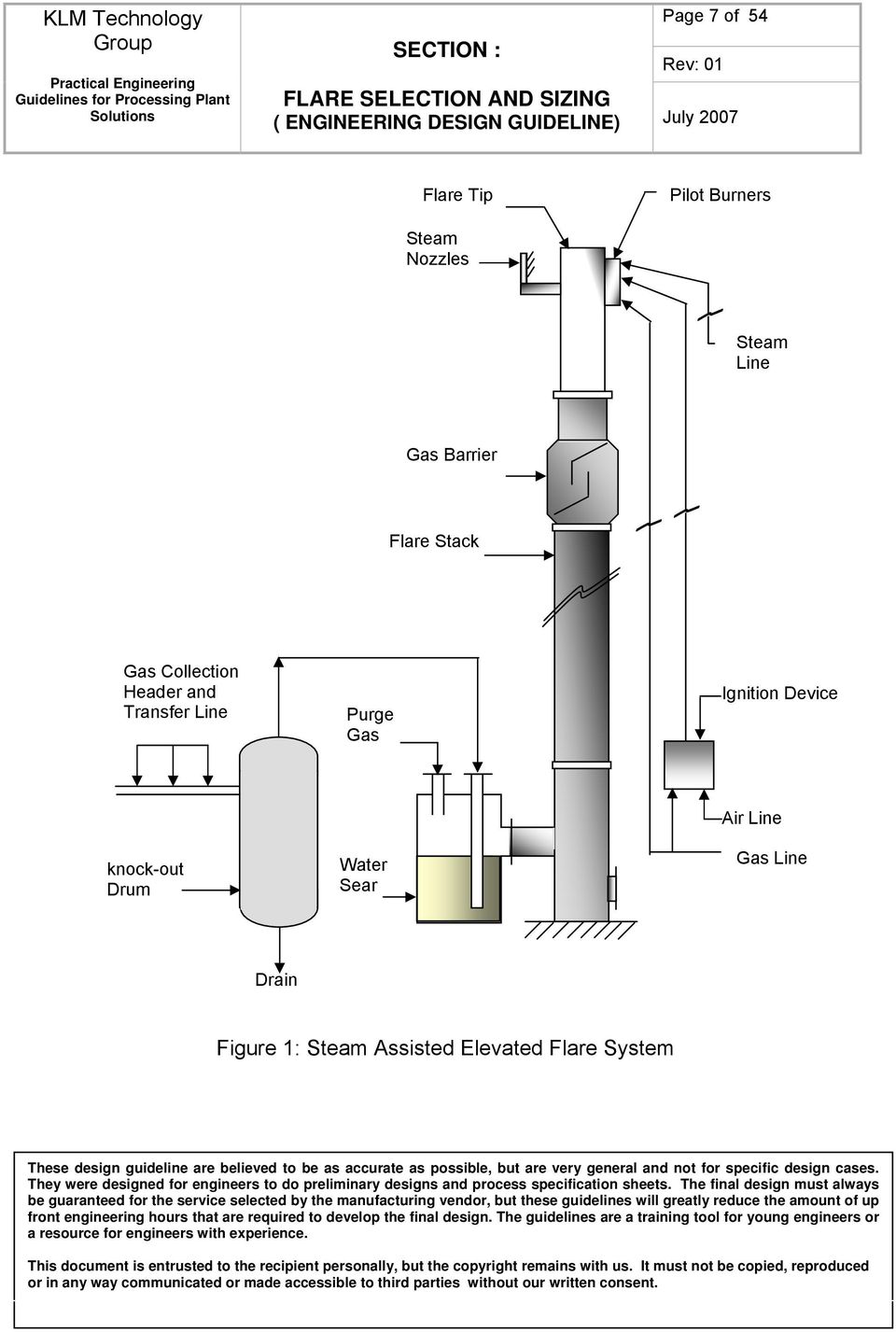

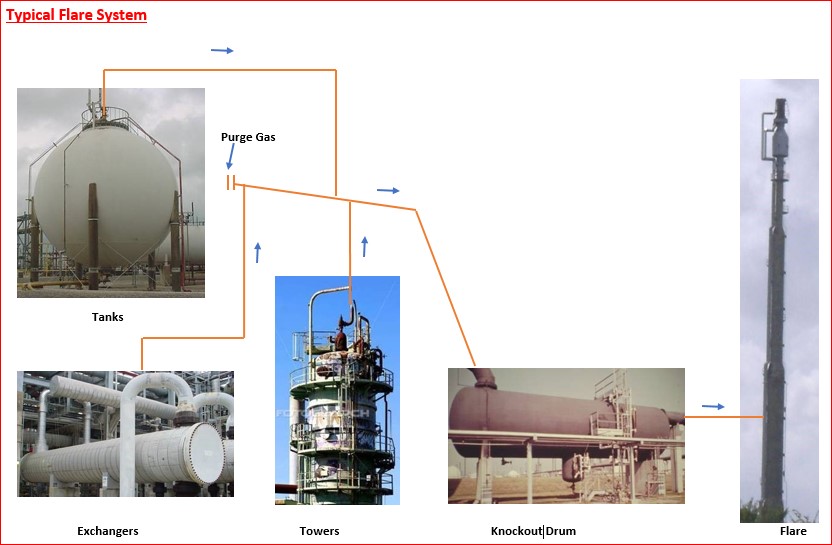

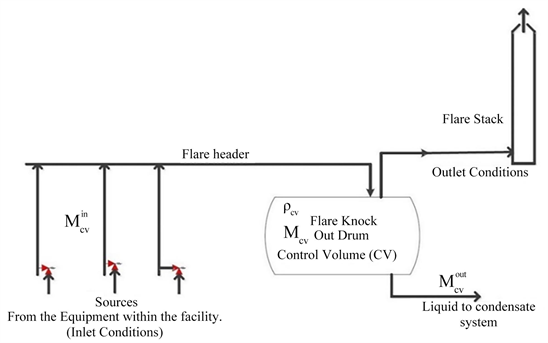

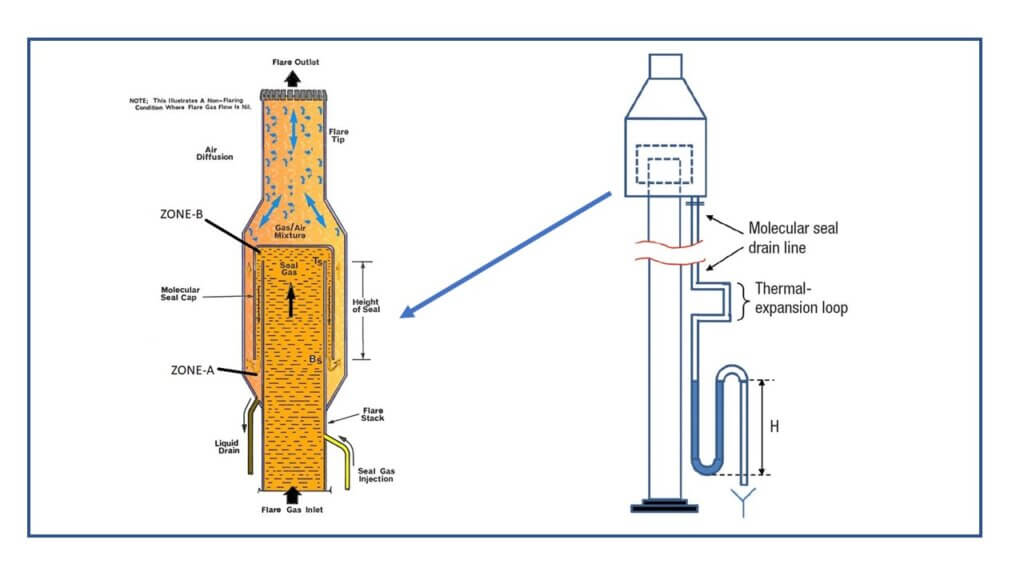

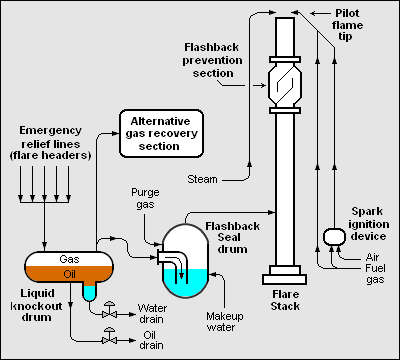

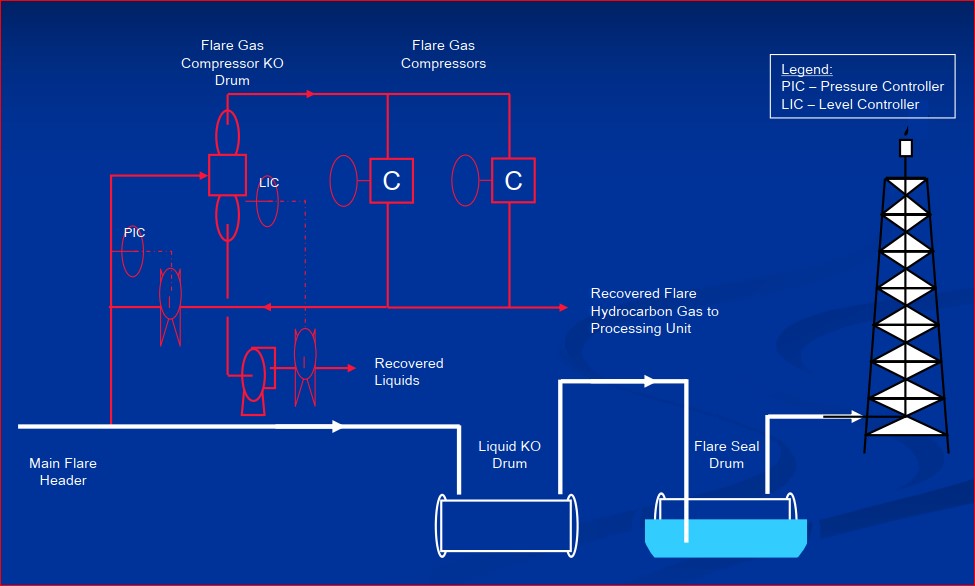

A flare system generally consists of an elevated stack means to maintain burning conditions at the top of stack and means to prevent flashback within the system. The flare system and its capacity are often overlooked or neglected through the numerous ongoing changes that occur at a facility. Home flare system design basis.

Flare is the proactive digital footprint monitoring solution for organizations. Of Process Equipment Design FLARE SYSTEMS SAFETY SELECTION SIZING AND TROUBLESHOOTING ENGINEERING DESIGN GUIDELINES Page 5 of 128 Rev. With the PSM standard introduced in the early 1990s many operating facilities made a proactive effort to re-establish their flare study baselines which was a great place to start.

03 JAN 2015 for engineers to do preliminary designs and process These design guideline are believed to be as accurate as possible but are very general and not for specific design cases. For Internal Approved for Sumitomo Chemical Co Ltd. Whenever industrial plant equipment items are overpressurized the pressure relief valves provided as essential safety devices on the equipment automatically release gases and sometimes liquids.

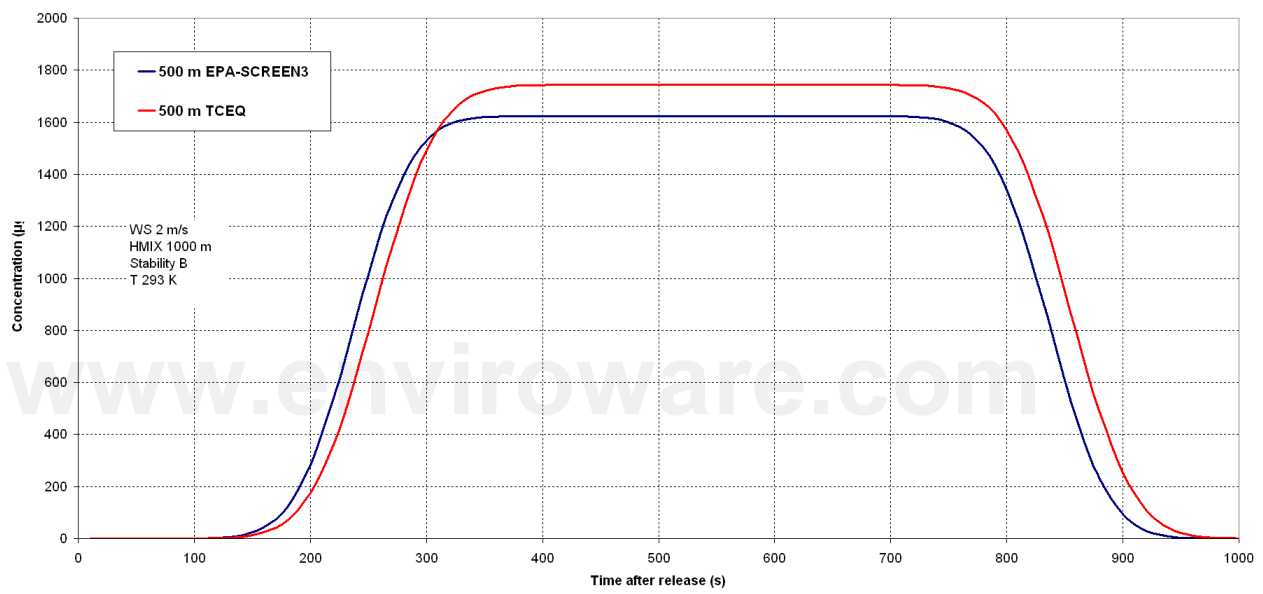

The Design Basis parameters are as follows. The US Environmental Protection Agency EPA published the AP-42 guideline for flare system emissions citing values that are essentially averages considering all of the CMA testing data.

Download JOELib 20 cheminformatics software.

2-3 23 Steam Injection Rates and Tip Design for Available Flare Test Data. With the PSM standard introduced in the early 1990s many operating facilities made a proactive effort to re-establish their flare study baselines which was a great place to start. For Internal Approved for Sumitomo Chemical Co Ltd. The burner often includes one or more pilots pilot igniters and pilot flame detectors. Pilot igniter controls are located near the base of elevated flares and atleast 100 ft. Unfortunately companies using the AP-42 data as their guideline for permitting elevated flares could be citing values that are far from accurate considering the wide range of. 22 Flare Vent Gas Constituents. Whenever industrial plant equipment items are overpressurized the pressure relief valves provided as essential safety devices on the equipment automatically release gases and sometimes liquids. 2-3 23 Steam Injection Rates and Tip Design for Available Flare Test Data.

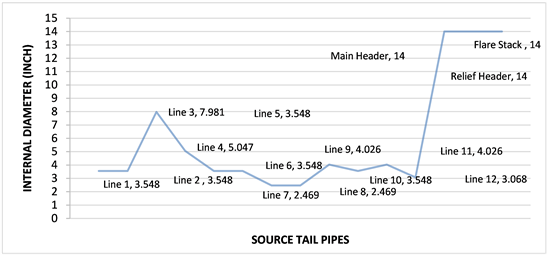

Our flare system design engineers incorporate the information into a Flare Load Summary Table which is the basis of the flare design. Process design basis development including vent stream characterizations. 22 Flare Vent Gas Constituents. 50 m 164 ft - as required. Regulatory design basis development including. Flare system design basis lummus project no. The process design project included completion of the following tasks.

Post a Comment for "Flare System Design Basis"