Osha Regulations For Spray Painting

Osha regulations for spray painting. 191535 b 2 If the ventilation fails or if the concentration of solvent vapors reaches or exceeds ten 10 percent of the lower explosive limit painting shall be stopped and the compartment shall be evacuated until the concentration again falls below ten 10 percent of the lower explosive limit. Gloves and coveralls protect your skin from absorbing chemicals. They are regulated by local councils as non-scheduled premises.

Booth should be designed to sweep air currents toward the exhaust outlet. Industries in which spray painting is encountered include. Containers under air pressure supplying spray nozzles shall be of limited capacity not exceeding that necessary for 1 days operation.

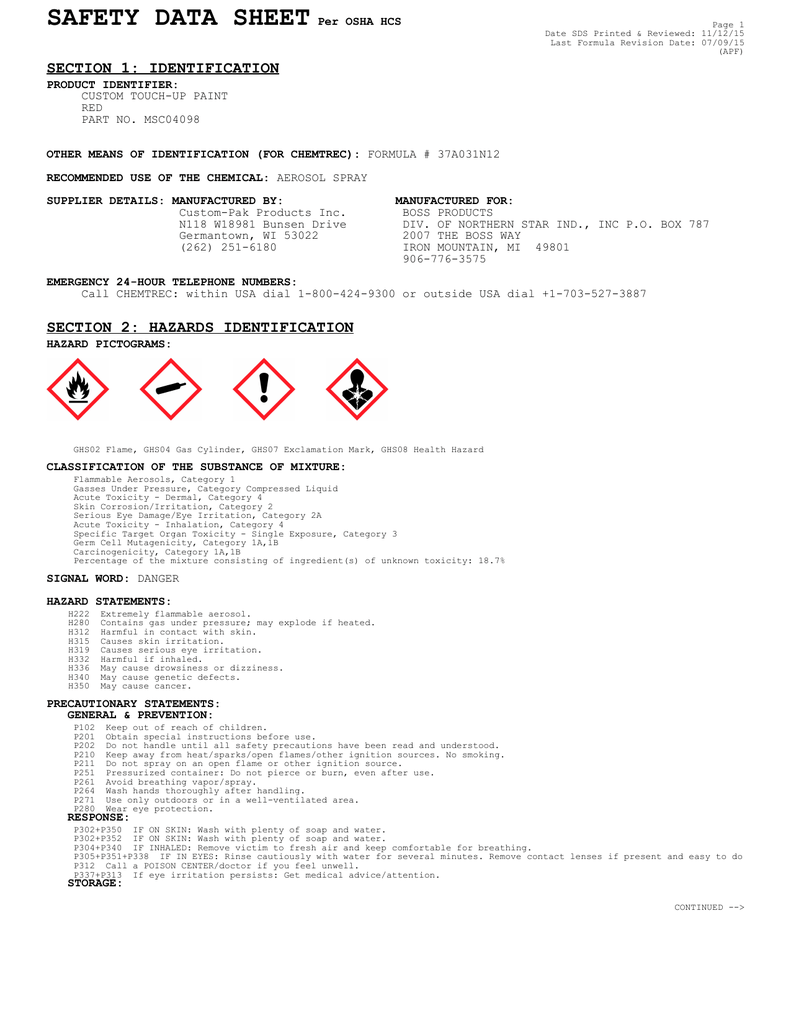

Also OSHA flammable storage regulations 29 CFR 1910106 refer to the requirements for electrical wiring storage capacity and arrangement of the chemicals. Spray guns paint pots and metallic parts of connecting tubing shall be electrically bonded and the bonded assembly shall be grounded to the vessel. These must comply with OSHA ventilation requirements.

Expert opinion may be required. The OSHA ventilation standard for general industry 29 CFR 191094 defines a spray-finishing operation as the employment of methods wherein organic or inorganic materials are utilized in dispersed form for deposit on surfaces to be coated treated or cleaned This may include such diverse activities as the application of flammable and combustible liquids such as paint in a spray booth or. The OSHA Standards for Spray Operations encompasses proper employee safety protocol for construction marine and.

Ventilation in spray facilities shall be sufficient to dilute flammable vapors to less than 20 percent of their lower explosive limit as specified in Section 5416. Spray booths should be constructed of steel concrete or masonry and securely and rigidly supported. 191535b13 All employees continuously in a compartment in which such painting is being performed shall be protected by air line respirators in accordance with the requirements of Subpart I of this part and by suitable protective clothing.

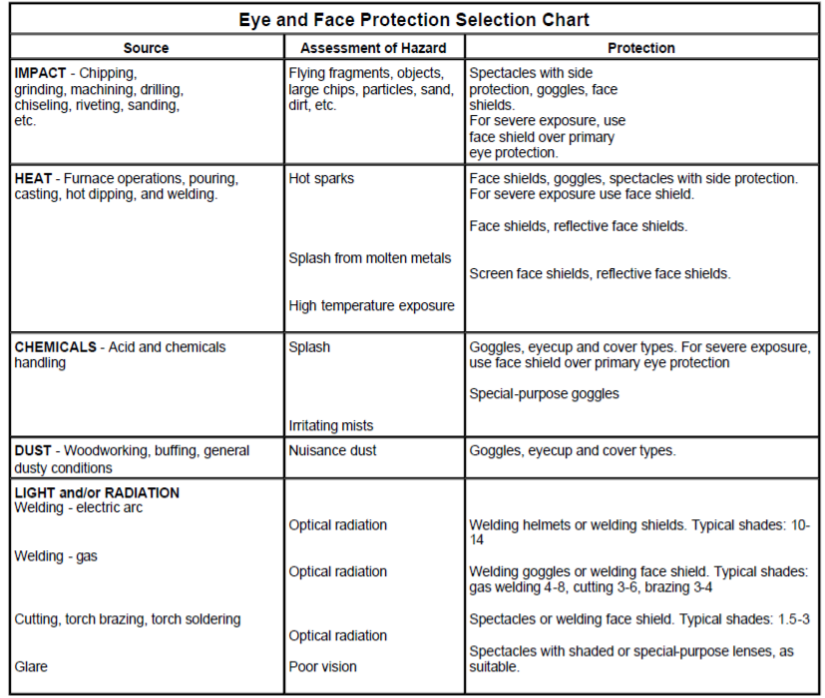

Preparing surfaces by sanding and cleaning can expose you to dust. If the concentration does not fall when painting is stopped additional ventilation to bring the concentration to below ten. Goggles or safety glasses protect your eyes from paint splashes during application and mixing.

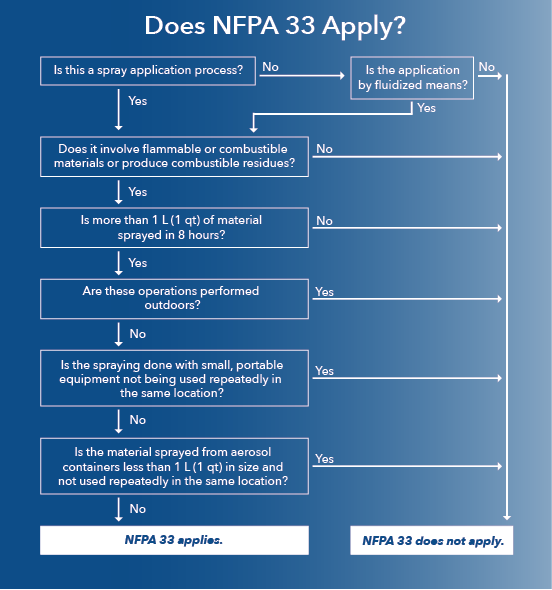

The checklist applies to spray-finishing operations involving flammable and combustible liquids such as paint varnish lacquer or stain. It includes the fundamentals of worker safety hazardous material containment and ventilation requirements.

They are regulated by local councils as non-scheduled premises.

Wear a respirator to protect yourself from dust spray paint droplets and the fumes from solvents and paints. They are regulated by local councils as non-scheduled premises. The average velocity of airflow intake through the face of the spray booth should be at least 100 feet per minute. Smaller-scale operations that use spray painting are not usually scheduled under the POEO Act and so do not require an Environment Protection Licence. Spray guns paint pots and metallic parts of connecting tubing shall be electrically bonded and the bonded assembly shall be grounded to the vessel. The general industry section of the OSHA regulations Part 1910 of the official standards contains rules that apply to almost any kind of spray or finish operation. Smash repairers or auto-refinishers auto mechanics. Electrostatic spraying operations can be conducted with an average airflow velocity of at least 60 feet per minute. The OSHA ventilation standard for general industry 29 CFR 191094 defines a spray-finishing operation as the employment of methods wherein organic or inorganic materials are utilized in dispersed form for deposit on surfaces to be coated treated or cleaned This may include such diverse activities as the application of flammable and combustible liquids such as paint in a spray booth or.

Spray booths should be constructed of steel concrete or masonry and securely and rigidly supported. Shall be designed and approved for such use. Spray booths should be constructed of steel concrete or masonry and securely and rigidly supported. Containers under air pressure supplying spray nozzles shall be of limited capacity not exceeding that necessary for 1 days operation. And shall be provided with a relief valve set to operate in conformance with the requirements of the Code for Unfired Pressure Vessels Section VIII of the ASME Boiler and. The OSHA ventilation standard for general industry 29 CFR 191094 defines a spray-finishing operation as the employment of methods wherein organic or inorganic materials are utilized in dispersed form for deposit on surfaces to be coated treated or cleaned This may include such diverse activities as the application of flammable and combustible liquids such as paint in a spray booth or. Ventilation in spray facilities shall be sufficient to dilute flammable vapors to less than 20 percent of their lower explosive limit as specified in Section 5416.

.jpg)

As a family-owned and operated business, we maintain a superior level of customer service that we believe is unparalleled by our competitors. We stay local so we can best serve you at a moments notice.

ReplyDeletehvac joshua tx

Address: 2840 FM731 Burleson, TX, 76028

Phone: 817-295-6519

business email: coolclimateac@yahoo.com